Product Catalogs and Descriptions - Download SMHS Brochure

Attachement

Attachement

| File | File size | Downloads |

|---|---|---|

Loadcell-Catalogue-starmhe

Loadcell-Catalogue-starmhe

|

4 MB | 155 |

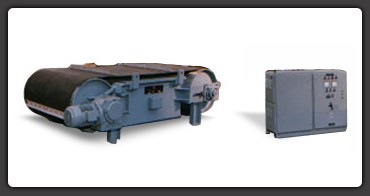

Overband Self Cleaning Type Electro Magnetic Separators

A must for separation of tramp iron pieces and for avoiding interruption and damage to major equipment in the process plants like Coal handling Plants of Thermal Power Stations, Cement and Sugar Industry, Foundries, Fertilizers & Chemicals Industries, Food and Plastic Industries etc.

STAR MATERIAL HANDLING magnets are available in copper/aluminium coil winding with F/H Class insulation and suitable for belt width ranging from 400 mm to 2000 mm, operating heights upto 700 mm with lifting capacity of steel ball of diameter 25 mm and above with maximum weight of 50 Kgs depending upon shape and size of tramp iron pieces.

Automatic Weighing & Bagging Machine

STAR MATERIAL HANDLING manufactures microprocessor based electronic belt weighers incorporating the latest state-of-the-art technology for continuous weighing applications in cement, steel, chemical, petrochemical industries and coal handling plants.

STAR MATERIAL HANDLING belt weighers consist of three major elements:

-

The weigh bridge assembly with precise strain gauge load cell/bending beam load

-

The belt speed sensor assembly, and

-

The electronic cabinet often referred as the totalizer or the integrator

Each serves a distinct function in the process of accurately weighing material moving on the belt. Different models of scale carriage are available depending upon the application, scale capacity and belt speed.

-

Capacities from a fraction of tonne to 10,000 TPH.

-

Simple rugged and unitized scale assembly for easy installation.

-

Super precision stainless steel strain gauge load cell applied in tension for highly accurate load measurement.

-

Special trunion bushes to absorb normal shocks and transverse forces.

-

Weigh idler deflection less than 0.025 mm at full load.

-

Brushless digital tacho provides accurate measurement of speed.

-

Fully digital with microprocessor and battery back-up memory.

-

Fully automatic tare and span calibration.

-

Self-checking diagnostics for fault indications.

-

Special electronic calibration facility for frequent calibration checks without handling standard weights.

Weighfeeder

STAR MATERIAL HANDLING manufactures microprocessor based digital weigh feeders as per design of HASLER International-France, incorporating their state-of-the-art technology for continuous control and proportioning application in cement, steel, fertilizer, chemicals, petrochemical and other industries.

STAR MATERIAL HANDLING manufactures microprocessor based digital weigh feeders as per design of HASLER International-France, incorporating their state-of-the-art technology for continuous control and proportioning application in cement, steel, fertilizer, chemicals, petrochemical and other industries.Principle of operation:STAR MATERIAL HANDLING Gravimetric weigh feeder is a variable speed small conveyor incorporating belt weighing and speed control system. The flow rate is held constant by varying the speed inversely with respect to belt load.Set point controller ( a built in feature in all Hasler controller ) allows setting of required rate and provides a signal to raise or lower the speed of the belt.For additional controls and communication facility, required signals are available from the weigh feeder control panel to connect it to a PLC or a supervisory computer either direct or using MODBUS/ PROFIBUS etc. making it a part of distributed digital control system. Measurement of flow rate and control are all through 32 bit microprocessor based digital techniques ensuring high reliability and accuracy to the level of 0.25% which is not known in the industry presently.For materials having sluggish flow characteristic mass flow bins, vibrators, screw feeders, rotary air lock feeders are provided to allow the material to lend themselves to control. |

Salient features :

Accuracy:0.25% to 0.5% through out the control range of 1:10 and 1:20. |

Metal Detectors

STAR MATERIAL HANDLING manufactures metal detectors as per Boekels’ design with latest technology incorporation integrating circuits, styroflex capacitors, metal film resistors, temperature compensated pot core transformers, active filters etc. These are widely used in:

Mining and material handling/processing industries to prevent damage to crushers, mills, elevators, feeding devices.

Chemical Industry to prevent damage to grinding mills and processing glass lined vessels and to avoid metallic contamination.

Wood and timber industries to prevent damage to saws, chippers, particle board presses etc.

Plastic and moulding Industries to prevent damage to press and moulds.

Food, Tobacco, Tea & Pharmaceutical industries to protect kneading machines and presses etc. and also to inspect final product for metallic contamination.

Clay and brick industries to protect moulds.

STAR MATERIAL HANDLING Metal Detector consists of search coil unit and electronic control unit. These are available in various Models depending upon width of conveyor belt and burden height. Sand bag marker for spot locating the detected metal contamination and auto testing device for periodic checking of sensitivity are provided as optional accessories.

Attachments

-

Loadcell-Catalogue-starmhe

Loadcell-Catalogue-starmhe

File size: 4 MB Downloads: 155